Other link

SIT-LOCK® Keyless Locking Devices are ideal for any shaft-hub connection application.

SIT-LOCK® units are suitable to connect any type of hub (flywheels, chain wheels, gears, levers, pulleys, eccentrics, couplings, etc.) and can be utilized in a varied range of industrial applications.

Features

- Help reduce the costs of the assembly

- Ideal for next-generation applications

- High axial and angular positioning accuracy

- Ideal for applications involving acceleration and deceleration

- Zero backlash

- Easy to mount

Keyless Locking Devices SIT-LOCK® available executions

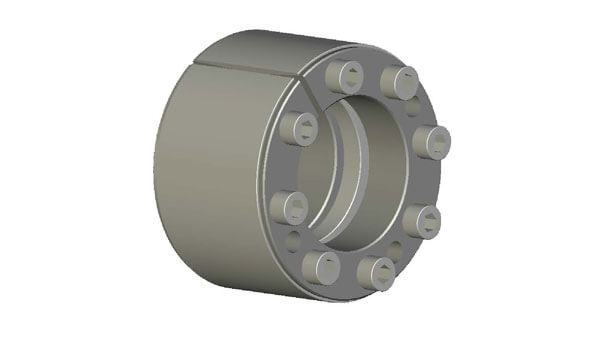

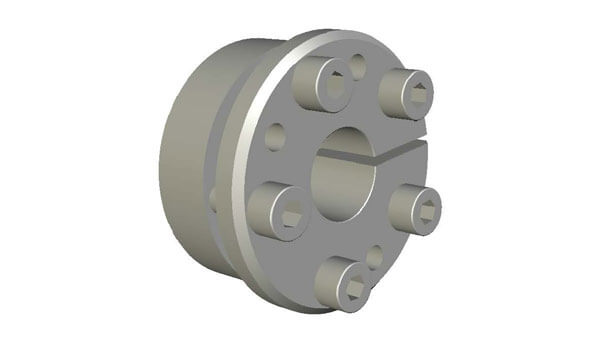

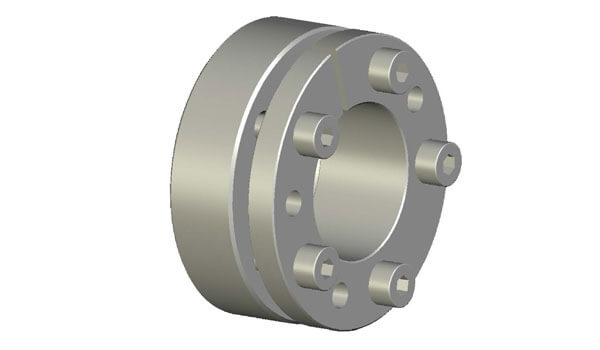

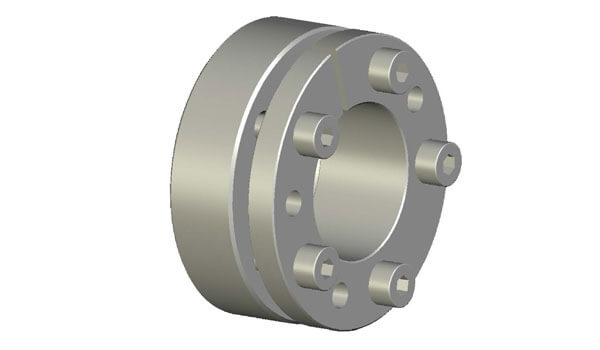

CAL1 executionNot self-centering

SIT-LOCK® locking assembly unit consists of four pieces with two inside double-cone rings joined through a set of tightening screws. It is recommended for medium torques and although it is not self-centering, it can be easily assembled and disassembled.

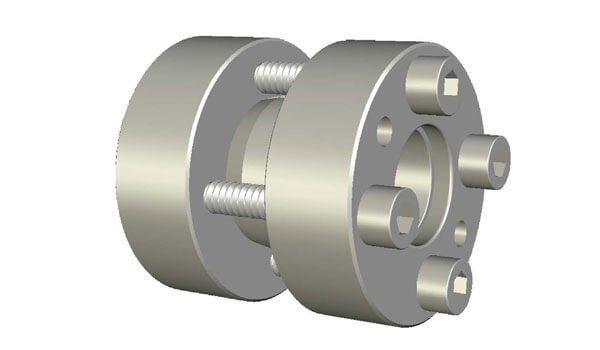

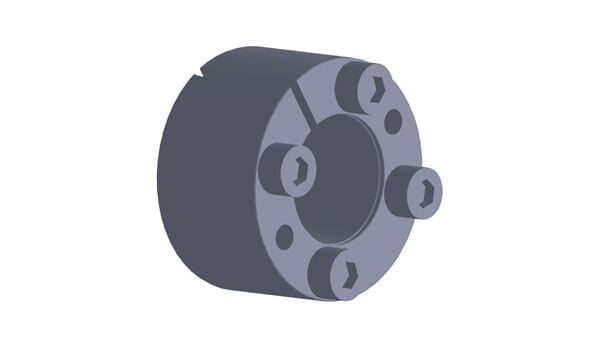

CAL2 executionNot self-centering

Locking elements consist of one internal and one external tapered rings. They are designed to work in combination a clamp flange, which can be bolted on hub or shaft depending on application need. The number of locking screws depends on the torque to be transmitted. SIT-LOCK® 2 requires very small axial installation dimensions. Up to 4 units can be arranged behind each other, so allowing high torques to be transmitted.

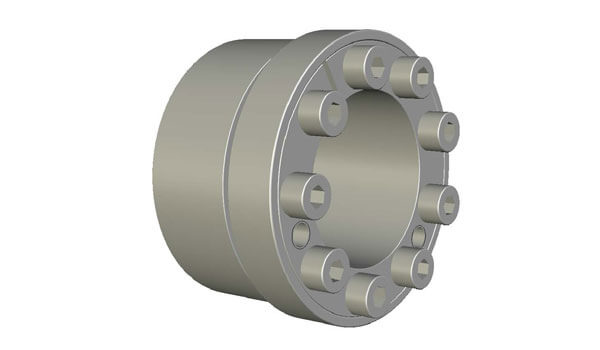

CAL3 executionSelf-centering

Locking assembly with single taper design. Consists of two tapered rings and a spacer. It has minimum overall dimensions in virtue of the reduced thickness of the cones. SIT-LOCK® 3 is suitable for the applications where small hubs are requested. It is recommended for mid-high torques and is self-centering.

During the installation of the unit no axial displacement of the hubs on the shaft occurs.

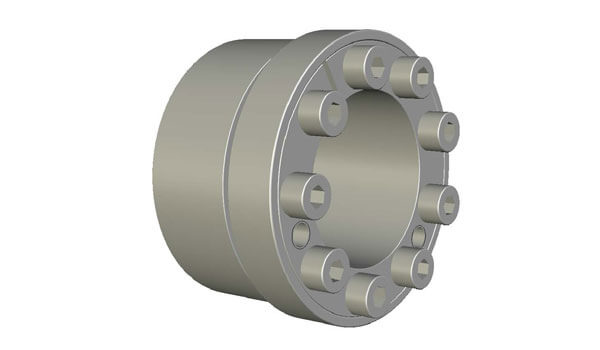

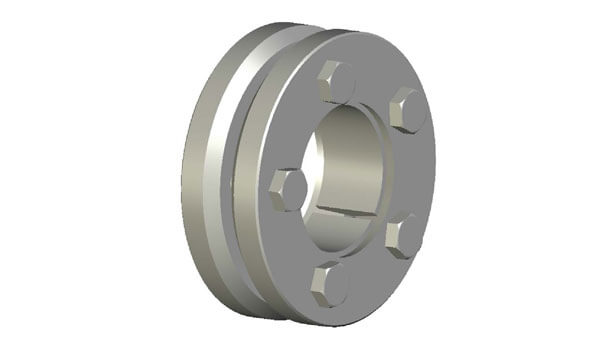

CAL4 executionSelf-centering

It is suitable for high torques and is self-centering. Recommended for applications that require high transmission values and excellent centering capabilities such as belt drums.

CAL5A executionSelf-centering

Locking assembly with single taper design. It is suitable for high torques. Provide good concentricity and self-centering. A small axial movement of the hub during the installation operation may occur. Applications in need of an accurate axial positioning are not recommended with this type of locking assembly.

CAL5B executionSelf-centering

Locking assembly with single taper design. It is suitable for high torques. Provide good concentricity and self- centering. It is recommended for medium torques and is self-centering. The flange design prevent axial movement during installation.

CAL6 executionSelf-centering

Locking assembly with single taper design. Provide good concentricity and self-centering. A small axial movement of the hub during the installation operation may occur. Applications in need of an accurate axial positioning are not recommended with this type of locking assembly. SITLOCK® 6 is suitable for applications with medium torques.

CAL7 executionSelf-centering

Locking assembly with single taper design. Provide good concentricity and self-centering. It is recommended for medium torques and is self-centering. The flange design prevent axial movement during installation. It is suitable for applications with medium torques, which need a very precise axial positioning.

CAL8 executionSelf-centering

Locking assembly with single taper design. The flange design prevent axial movement during installation. SIT-LOCK® 8 has a very small axial dimension, is self-centering and has been designed to suit various shaft diameters although the overall dimensions are the same. SIT-LOCK® 8 is recommended for applications with medium torques, which need a good axial positioning. The limited number of screws make the installation fast.

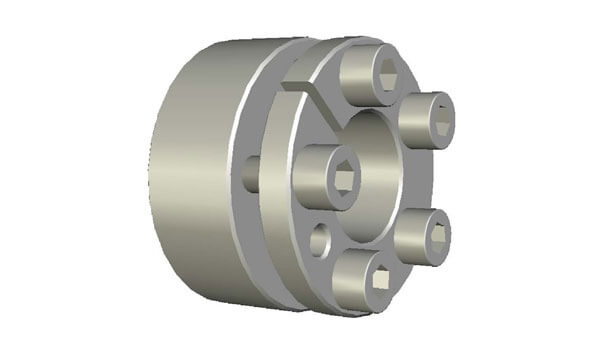

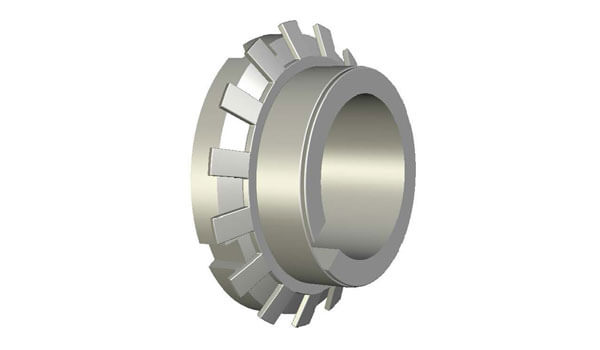

CAL9 executionNot self-centering

Consists of two tapered rings and a lock nut. In virtue of the simple design, very fast assembly/disassembly is allowed. SIT-LOCK® 9 is suitable for applications with small-medium torques.

CAL10 executionExternal

SIT-LOCK® 10 are shrink disk couplings with double taper design. They offer a very easy angular timing and axial adjustment of shaft ends. They transmit high torque and bending moment without keys and offer a low cost solution for shaft-to-shaft rigid connection.

CAL11 executionExternal

Shrink discs are external locking devices, which are installed over hub projections. By locking the screws, radial pressures act on the hub allowing an effective and solid connection. Recommended for medium and high torque. SIT-LOCK® 11 is also in versions “SPLIT” and “HALF” for special applications.

CAL12 executionSelf-centering

SIT-LOCK® 12 is self-centering unit. Convenient series, it is suggested, only for big quantities, in the applications with medium torques.

CAL13 executionSelf-centering

SIT-LOCK®13 is very close to the standard type SITLOCK® 9 but it is manufactured in a longer execution. It is made of two tapered rings and a locking nut.

CAL14 executionExternal

SIT-LOCK® 14 are shrink discs for external, series “14”, are characterised by a single tapered ring instead of opposite tapers of the 3 pieces shrink discs SIT-LOCK® series “11”. The SIT-LOCK® 14 Shrink discs offer a better concentricity and centering and a very good balancing. These features make the series highly suitable for mid-high speed applications. SIT-LOCK® 14 are manufactured in five different types.

CAL15 executionSelf-centering

Suitable for servomotors and small pulleys. It gives an axial force, similar to the clamp load of the screws, and an axial movement that can be used to set ball bearings.